John Hill, marketing services manager for Parker Hannifin’s pneumatics division, looks at how the food industry directives and standards are driving pneumatics technology in food, splash and non-food areas.

John Hill, marketing services manager for Parker Hannifin’s pneumatics division, looks at how the food industry directives and standards are driving pneumatics technology in food, splash and non-food areas.

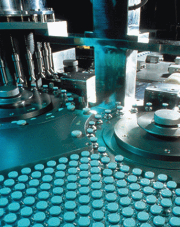

Pneumatics is a widely used technology in the food and beverage sectors, with approximately 90 per cent of all companies using compressed air in some aspect of their business. Indeed, it provides a safe and reliable power source that is ideal for controlling many different processes, along with handling and positioning tasks in food production and packaging operations.

However, the challenges presented by the nature of these applications means that pneumatics equipment has to operate under some of the toughest conditions. Not only does equipment have to be fast, reliable and easy to maintain, it also has to withstand often aggressive food ingredients and be suitable for internal CIP (clean in place) and external high pressure washdown. It also has to comply with environmental, safety and hygiene legislation that includes directives such as ISO14159:2002 Safety of Machinery, which specifies the intended use of machines, and EN1672 Food Machinery – Basic Concepts, that focuses on the common hygienic requirements for food processing machinery in Food Areas, Splash Areas and Non-Food Areas.

EN1672 has some interesting implications for companies manufacturing equipment for the food sector, as it effectively controls the materials of construction and the design and configuration of the components. For example, machinery used in Food Areas must have surfaces that are smooth and self draining, with corrosion resistant, non-toxic and non-absorbent materials. Even in the Non-Food Area, exposed surfaces should be corrosion resistant and both easy to clean and disinfect.

EN1672 has some interesting implications for companies manufacturing equipment for the food sector, as it effectively controls the materials of construction and the design and configuration of the components. For example, machinery used in Food Areas must have surfaces that are smooth and self draining, with corrosion resistant, non-toxic and non-absorbent materials. Even in the Non-Food Area, exposed surfaces should be corrosion resistant and both easy to clean and disinfect.

It is also important to remember that food processing and production facilities are designed around the internationally recognised HACCP (Hazard Analysis Critical Control Point) system for food safety management. This defines seven key principles that should be followed, from initial hazard analysis, through the determination of critical control points, to identification of control procedures, monitoring and record keeping.

As a result it is vital technology in the food and beverage sectors must conform to standards such as EN1672 without creating risk to production in line with HACCP principles.

This has spawned new pneumatics equipment that has been developed with these standards in mind. For example, there is a trend to remove sensors from the outside of cylinder bodies using encoder technology that allows positioning to be determined from internally located electronic and electromechanical devices.

Parker Hannifin has launched a range of ISO standard stainless steel cylinders, which feature a special scraper ring, piston rod bearing and seal system with self lubricating characteristics suitable for dry operation which is critical under regular wash down. Furthermore, pneumatic end cushioning allows exact setting, permitting heavier loads and higher speeds to be accommodated, while all moving parts are pre-lubricated with food industry approved grease.

Along with the latest stainless steel cylinders, conventional aluminium bodied units are now available with smooth, clean line surfaces to ensure cleaning fluids can flow effectively over each device. Improved actuator body designs and end caps enable them to be self draining and prevent the ingress of contamination, even when subjected to regular washdown.

In addition, a new range of stainless steel air motors, such as the P1V-S series from Parker, has been developed to provide a hygienic, efficient and cost-effective alternative to conventional AC and DC devices in food grade applications. These innovative devices feature an air motor and planetary gearbox, which is lubricated with USDA-H1 standard grease, built into a polished stainless steel housing, which is sealed by a fluor-rubber O-ring to prevent the ingress of moisture, debris and other particulate contamination. As importantly, the cylindrical design of these air motors mean there are no pockets in which dirt or bacteria can accumulate, while a further O-ring seals the two halves of the air motor enhancing cleanliness further.

In addition, a new range of stainless steel air motors, such as the P1V-S series from Parker, has been developed to provide a hygienic, efficient and cost-effective alternative to conventional AC and DC devices in food grade applications. These innovative devices feature an air motor and planetary gearbox, which is lubricated with USDA-H1 standard grease, built into a polished stainless steel housing, which is sealed by a fluor-rubber O-ring to prevent the ingress of moisture, debris and other particulate contamination. As importantly, the cylindrical design of these air motors mean there are no pockets in which dirt or bacteria can accumulate, while a further O-ring seals the two halves of the air motor enhancing cleanliness further.

Equally critical is the quality of the compressed air that will be fed downstream to pneumatics components, as contamination can present a significant threat to the performance of systems, for example, affecting the efficiency and operating life of internal seals and, most importantly, the quality of process air. Indeed, it is vital all potentially harmful or dangerous contaminants are removed in order to protect the consumer and provide a safe, cost-effective production facility.

To address the issue, Parker has designed a range of high performance filters that remove oil and water aerosols down to 0.01mg/m³ and also particulate contamination down to 0.01µ. Its Oil-X Evolution range of filters has been developed to provide the lowest possible operational costs, while providing the highest air quality standards that exceed the requirements of ISO 8573-1:2010.

To address the issue, Parker has designed a range of high performance filters that remove oil and water aerosols down to 0.01mg/m³ and also particulate contamination down to 0.01µ. Its Oil-X Evolution range of filters has been developed to provide the lowest possible operational costs, while providing the highest air quality standards that exceed the requirements of ISO 8573-1:2010.

These developments mean compressed air and pneumatics equipment remain pivotal elements to manufacturing processes in today’s food and beverage production facilities. Most importantly, these latest technologies ensure compliance with the range of clearly defined legislation, while enabling OEMs and end users alike to improve both the productivity and profitability of their operation and ensure that product quality remains at an all time high.