Biopharmaceuticals, or biologically produced medications, are rapidly being used to treat a host of chronic and genetic conditions.

Expected to be worth $535 billion by 2027, the biopharmaceutical market is currently undergoing significant growth.

However, production issues are hampering the industry’s ability to meet demand.

Now a research team from Pennsylvania State University is looking to tackle one of the major bottle necks in biopharmaceutical production – purification and filtration.

Led by Dr Andrew Zydney, 14 graduate students from the university are investigating system effects, including that of different operating pressures on membrane filtration. Membrane filtration is an essential process that removes any remnants of the host cells used to create the biopharmaceutical and viral particles introduced during the production process.

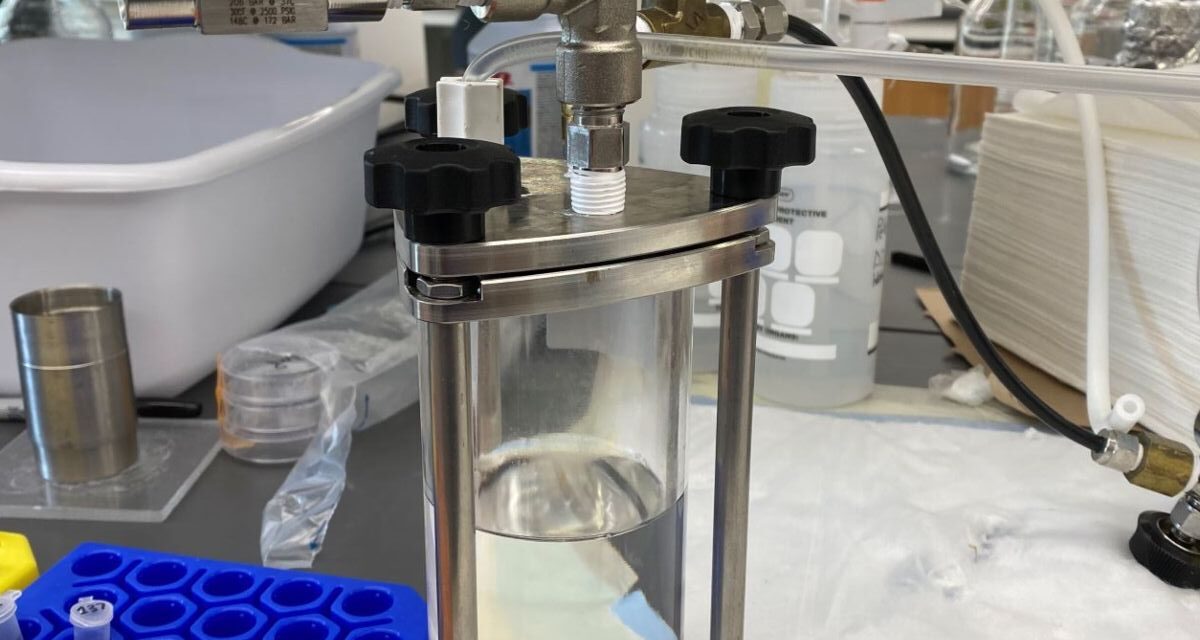

Using four SR-Tek transparent pressure vessels, the team is aiming to understand under what conditions biopharmaceuticals can get trapped within the membrane and in what circumstances viral particles and other contaminants can pass through the filtration.

Speaking about the importance of the research, Joshua Peles, PHD student at Penn State, said: “These medications are often used to treat people with immune system suppressant illnesses where the presence of a viral particle could prove fatal. Contamination events have led to several batches of biopharmaceuticals, which could have gone on to help 1,000s of patients, being scrapped entirely. At the same time, these are often essential treatments, which if delayed by production processes can again have a damaging impact on patients.

“Making use of SR-Tek’s transparent pressure vessels we’re looking to enable biopharmaceutical companies to increase both the yield and purity of their output and ultimately improve the lives of the patients they are looking to treat.”

Initial results of the 19-month ongoing Pennsylvania State University study by Zydney and Peles are due imminently.