Who is SCHMIDT Technology?

Who is SCHMIDT Technology?

The company was set up in 1938 and is a family owned, medium sized technology leader in the fields of writing instrument technology, presses for forming and joining and advanced sensor technology. The company employs more than 400 staff worldwide and combines a global presence with innovative creativity and a highly sophisticated manufacturing facility in Germany all of which form a solid foundation for the success of the future oriented business.

The right amount of stock required

In order to provide manufacturing with exactly the right amount of material SCHMIDT Technology must have complete transparency of the amount of material held at any time in the FIFO racks. Only in this way can the replenishment process be optimised and excess stockholding minimised. The easy to install retro-fit StockSAVER system provided the answers. StockSAVER makes sure that FIFO shelves never run dry, solves all of the traditional Kanban problems and renders previously required safety stocks unnecessary.

Typical Kanban problems solved

A well organised Kanban system brings many advantages to the operation but in reality leads to a lack of clarity regarding stock levels held on the FIFO shelves. Is there enough stock in place for the orders on hand?

A well organised Kanban system brings many advantages to the operation but in reality leads to a lack of clarity regarding stock levels held on the FIFO shelves. Is there enough stock in place for the orders on hand?

Do Kanban cards get lost or damaged? Does the milk-round actually collect them in a timely fashion? Questions like this often lead to increasing safety stocks held locally in order to avoid production coming to a grinding halt.

These questions have also been concerning SCHMIDT Technology. The company manufacturing process calls for sub-components to be manufactured according to a defined production plan resulting in the assembly of the finished product – “we don’t manufacture parts for stock” comments Production Manager Ulrich Heck. “The question of whether there was too much or too little stock of components in was fundamental in establishing the degree of transparency in the logistics process.”

StockSAVER – the solution from WERMA

Bins in the FIFO flow racks contain the refills which are awaiting the barrels coming in from the mould shop before being worked on further. Because there is no additional WIP stock it is important to have excellent transparency of the actual content of the FIFO flow racks to prevent too much or too little stock being held there and to allow the flow of production to run smoothly.

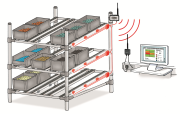

„To begin with we started looking at an E-Kanban system,” explains Steffen Moser, Lean Manager at SCHMIDT Technology. „However everybody involved with the process needs unequivocal transparency of the actual current status on the line” continues Moser. SCHMIDT Technology established contact with WERMA very early on and began to learn about the StockSAVER system. Sensors monitor the number of bins on the FIFO flow racks and transfer this data wirelessly to the StockSAVER software.

StockSAVER offers a robust error-free system as it is no longer necessary to scan withdrawals of stock neither is there a danger of duplicate bookings being made nor are arithmetically calculated stock level errors possible. The intelligent monitoring of the stock levels on the flow racks ensure full transparency of stock and the automatic issue of replenishment orders safeguards against stock-outs or incorrect items being replenished.

Test run with WERMA‘s StockSAVER

SCHMIDT Technology fitted 17 shelves with three sensors per shelf and on one shelf installed 4 sensors. The sensors monitor the movement of the bins and transfer this data via the SmartBOX to the software wirelessly. In this way a digital version of the real-time status of the shelves is created which gives everybody a perfect overview of stock levels on the shelves In addition clear instructions are given automatically to Logistics and Planning on the replenishment requirements and priorities. Analyses and data export allow lasting improvement measures to be made to the process.

Replenishment orders and lists are created not only by degree of urgency but also grouped together according to the type of material thus making picking and prepping an easier and less stressful process for staff. “Information on replenishment time, how often a shelf was emptied and replenished is information I simply didn’t have before,“ continues Lean Manager Steffen Moser „and even the pre-production software version we tested together with the hardware functioned perfectly without any kind of teething problems.”

Further applications planned for StockSAVER

Schmidt Technology is already planning to use StockSAVER in another division of the company. “We can already see real advantages in using StockSAVER as a transport Kanban system compared with other alternatives we have looked at. The implementation was superb the system is so easy to use and easy to understand. Now that we can export and analyse data means that we can also act and not just react” concludes Steffen Moser. “It is great that the data and analyses are so transparent and give us many points for further discussion and make lasting improvements to our processes” stresses Oliver Schmidt, Managing Director. “Thanks to StockSAVER we have been able to uncover lots of improvement potential and in the future will be able to reduce our production times and reduce the amount of stock in circulation whilst maintain the same level of component availability.”

The sensor fitted to the FIFO rack ensures complete transparency of stock levels

The SmartBOX transmits the data collected by the sensors wirelessly

The intelligent StockSAVER software creates the digital twin of the FIFO shelves connected to the network giving the user a comprehensive and accurate overview of stock levels on the shelves.

Lean Manager Steffen Moser is very pleased with the advantages provided by StockSAVER.

About WERMA

Werma Signaltechnik GmbH & Co. KG is an international company with more than 350 employees located in 7 sites, including the UK base in Wellingborough. The family owned business, established in 1950, is one of the global leaders in signal devices and is the technology leader in its field.

The company established an industry standard with its modular signal tower range. Today WERMA manufactures a wide range of optical and audible signal devices as well as intelligent systems for process optimisation in general industry and logistics. In a world-wide first, WERMA signal towers can be wirelessly linked to provide a simple retro-fit alternative to traditional machine monitoring and data collection systems.

WERMA UK Ltd

Tel: 01536 486930

www.werma.co.uk