One of the largest growth markets for static thermal imaging cameras is safety. Many infrared cameras are radiometric and therefore able to measure and analyse temperature. There are others that output this data via email to flag-up problems or to trigger an alarm or synchronised function

One of the largest growth markets for static thermal imaging cameras is safety. Many infrared cameras are radiometric and therefore able to measure and analyse temperature. There are others that output this data via email to flag-up problems or to trigger an alarm or synchronised function

Infrared cameras are able to provide live, high resolution images and some have a time-saving measurement masking feature which enables areas of thermal interest to be selected. They remain fully operational, day and night, even when smoke or mist clouds the field of view. Sophisticated software allows multiple cameras to be run simultaneously and standard protocols such as GigEVision and GenICAM substantially cut down their integration time.

In short, a thermal imaging camera is more than just a temperature measurement device. It provides comprehensive, cost-efficient monitoring and control in a single, compact package that can be used on its own or combined with other monitoring technologies.

Quantifying the risk

More often than not the risk areas in a production process and the assets most critical to manufacturing continuity are easily identified. The challenge is in knowing exactly where or when a problem might occur and also quantifying its severity.

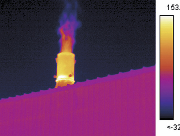

For certain industries this ability is vital. In oil and gas production and power generation there is a fundamental need to detect flares automatically and continuously to prevent the outbreak of fire. Similarly the integrity of critical vessels and infrastructure has to be monitored to avoid costly downtime and ensure on-site safety.

For certain industries this ability is vital. In oil and gas production and power generation there is a fundamental need to detect flares automatically and continuously to prevent the outbreak of fire. Similarly the integrity of critical vessels and infrastructure has to be monitored to avoid costly downtime and ensure on-site safety.

Infrared meets all the needs with ease. A camera can be installed discretely almost anywhere to keep an eye on production processes, safeguard plant and assets and measure temperature differences so the criticality of the situation may be assessed. The technology is ideal for any industry where fire prevention, effective asset management and fixed, mounted predictive maintenance are important.

Typical applications

Bulk storage of any combustible material such as coal, wood or waste can lead to fire risk. Self-ignition generally starts in the bottom of the stockpile but by continuous monitoring of the surface, subtle changes can be detected early and action taken.

A good example of an effective solution is one supplied by systems’ integrator Enelex to monitor a coal storage facility. The large size of the storage yard meant the use of portable infrared was not a practical solution for this critical task. Only a fully automated system would be able to provide constant monitoring of the many thousands of tons of coal.

The system is based on Flir A-Series cameras mounted on five steel masts at strategic locations around the site. They are configured to generate a direct alarm output to an operator if previously defined maximum temperature thresholds are exceeded. Acoustic and display alarms on a monitor draw the operator’s attention to the possibility of a spontaneous fire. Data transfer is via 3km of fibre optic cables to the control room.

The system is based on Flir A-Series cameras mounted on five steel masts at strategic locations around the site. They are configured to generate a direct alarm output to an operator if previously defined maximum temperature thresholds are exceeded. Acoustic and display alarms on a monitor draw the operator’s attention to the possibility of a spontaneous fire. Data transfer is via 3km of fibre optic cables to the control room.

A Flir A-Series camera is also central to a new fire prevention system called PYROsmart. The system, developed by German company Orglmeister, can scan a large area and all the thermal images that are taken are stitched together to create a single composite image that is continuously updated.

By combining all the 640 x 480 images created by the Flir camera, an image of up to 9,600 x 9,600 pixels can be achieved. The user can easily set various types of rules in the PYROsmart system and any violation will result in the automatic sounding of an alarm.

A thermal imaging camera is also a good alternative to its visual counterpart in flare detection. Changes in temperature and pressure during the production process at oil and chemical processing plants can generate excess gas. To protect staff and equipment this pressure is relieved by diverting this excess gas to a flaring device. Here the infrared camera’s ability to see through smoke and be equally effective day and night really comes into its own.

In summary

Thermal imaging is proving to be valuable in safety applications both as a solution on its own and in systems combining visual and thermal technologies. Its scope is said to make it widely commercialised and affordable. And when safety, loss of property, water damage from fire-fighting and loss of production are factored in infrared could turn out to be a modest investment.

Flir Systems

T: +44 (0)1732 220011