BS&B is a leading global producer of bursting disks, buckling pin devices and explosion protection solutions designed for industrial processes. Founded in 1931, the company’s innovative history spans more-than-eight decades with BS&B engineers responsible for developing much of the overpressure relief technology in use today.

BS&B is a leading global producer of bursting disks, buckling pin devices and explosion protection solutions designed for industrial processes. Founded in 1931, the company’s innovative history spans more-than-eight decades with BS&B engineers responsible for developing much of the overpressure relief technology in use today.

BS&B offers a comprehensive portfolio of products and services that meet and exceed rigorous industry standards for quality and reliability. Our integrated solutions have been time-tested and fine-tuned to deliver maximum value and greater efficiencies to individual engineering processes.

BS&B offers a broad range of overpressure relief devices, which are fast, accurate and dependable. By offering a wide selection, BS&B can meet your specific needs.

• Disk sizes ranging from 3mm to 1120mm

• Pressures from mbar g to 6900 bar g

• Custom engineered and designed bursting disks

• Fast-acting and quick-reset, while installed, Buckling Pin Devices

• Dust Explosion Management Solutions

BS&B and its affiliates offer a network of worldwide engineering, manufacturing and support services. Plus access to more than 125 fully trained representative companies.

Seminars

Seminars

BS&B provides Seminar/Workshops on the following topics:

• Basic Information on Bursting Disks and Bursting Disk Selection

• Demonstration of Burst Characteristics

• Relief Valve Isolation and Testing

• Codes, Safety, Government Regulation

Codes and Standards

Since designing the first bursting disk in 1931, BS&B Safety Systems has set the standards in the industry.

• Originated patents on 90% of all bursting disks products

• Proven commitment to quality and innovation BS&B disks are manufactured in conformance with the requirements of the following international codes and standards.

• ASME Sections VIII & III (UD stamped)

• EC Pressure Equipment Directive

• EN ISO 4126-2 (pending)

• BS 2915

• ISO 6718

• TUV AD Merkblatt A1

• SVTI

• Stoomwezen

• ISO 9001

High-Quality Manufacturing

BS&B manufacturing facilities have achieved the prestigious ISO 9001 Certification by passing a series of independent audits, proving the company has modern, quality control systems to help assure consistent quality products are provided to the marketplace. The audits assess all of a company’s systems that affect quality; from the ordering of raw materials to manufacturing, testing and final distribution. What this means to you is that BS&B conforms with established international standards of quality. You can rest assured that any product that bears the BS&B name has passed a rigorous set of tests and meets the highest industry standards.

• Patents on all major Bursting Disk products

• Proven commitment to quality, innovation and service

• Worldwide production facilities

• Largest research and development staff in the Bursting Disk industry

• Highly qualified engineering and manufacturing personnel

Commitment to excellence can be seen in BS&B’s Bursting Disk designs. This commitment ensures the product you receive will operate safely and efficiently.

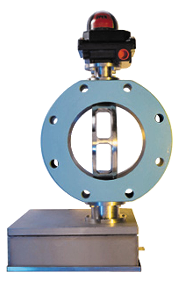

Buckling Pin Valves

Buckling Pin Valves

BS&B produces fast acting/quick opening buckling pin devices (inline and angle) designed to protect personnel, equipment and environment from the dangers of overpressure. Buckling pin devices provide the accuracy of a rupture disk. However, because of because of the devices quick and easy field-reset and ability to remain installed during reset, plant downtime is dramatically reduced. Sizes range from 2” to 60” for buckling pin relief valves. In fact our 60” BPRV, first released in 2007, was the world’s largest ASME certified pressure relief device in the world. Buckling Pin Angle Valve was the first API-526 piping configuration buckling pin valve. Its sizes are 1”x1.5” to 8”x10”.

BPRV™

Buckling Pin Relief Valve

The BPRV is an in-line pressure relief device which offers quick and simple field reset without removal from the piping system. This nonreclosing pressure relief device provides practical technology for the protection of applications containing one or more of the following conditions:

• Continuous Processing (fast reset in the line)

• Hazardous Service (limits operator exposure)

• Large Line Size (convenient reset in the Line)

• High Capacity

• Inaccessible Location (external reset in the line)

• High Operating Ratio

• Frequent Operation (fast reset in the line)

Explosion Protection Solutions

BS&B has proven itself to be the fastest growing manufacturer of industrial explosion protection technology with products designed to meet the requirements of the OSHA Combustible Dust National Emphasis program and the requirements of NFPA 654, and NFPA

documents 68 and 69. Products include:

• Equipment protection by explosion venting direct to atmosphere

• Equipment protection by flameless explosion venting

• Building protection by explosion venting

• Equipment protection by suppression

• Equipment protection by chemical isolation

• Equipment protection by mechanical isolation

• Dust testing for combustion characteristics

• Inspection of prevention and protection measures