An infrared vision system from Flir is helping a manufacturer of pasta and rice salads packed in plastic, lidded bowls, to solve a costly wastage problem.

An infrared vision system from Flir is helping a manufacturer of pasta and rice salads packed in plastic, lidded bowls, to solve a costly wastage problem.

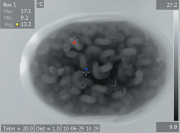

The manufacturer found the traditional vision system it was using could not detect whether the lid had been successfully applied to the bowl. This caused wastage as the next step is the application of a label to seal the product and identify its content. Without a lid, the label came into direct contact with the food, instantly contaminating it.

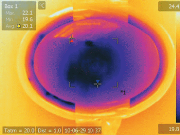

The problem in this application was the lid’s thinness and transparency. Thermal Imaging equipment supplier, Thermascan used a Flir A320 infrared GigEVision and GenICAM compatible thermal camera featuring a trigger/synchronisation capability. The Flir camera detects the minute difference in temperature between a salad bowl with a lid and one without. “We are looking at a temperature variation of maybe just 1.5 to 2°C,” says Thermascan’s Dave Blain. “This is an effective and accurate way of determining whether the lid has been successfully applied.”

If the camera detects a missing lid it activates an alarm and stops the line so only single products are scrapped and downtime is minimised. In addition to triggering the missing-lid alarm, the Flir camera’s I-O ports allowed it to be easily linked to the established vision system. The combined arrangement therefore allows the food processor to detect automatically that the container has been accurately filled, the product profile is correct and the lid is in place, ready for the label.

If the camera detects a missing lid it activates an alarm and stops the line so only single products are scrapped and downtime is minimised. In addition to triggering the missing-lid alarm, the Flir camera’s I-O ports allowed it to be easily linked to the established vision system. The combined arrangement therefore allows the food processor to detect automatically that the container has been accurately filled, the product profile is correct and the lid is in place, ready for the label.

Blain says: “The digital I-O connector on the camera can be used for various food processing tasks. For example it allows us to link the output from the Flir camera to a thermostat so that the operating temperature can be automatically adjusted. The technology is also suitable for detecting optimum temperature for cooked food.”