For more than 60 years, U-S Safety Trolley has been a leader in customisable, flexible power distribution for industrial sites. Recognising that electrical joints were the most common sources of problems in crane electrification, U-S Safety Trolley engineers designed four unique “no-joint” products to meet the needs of industry: Span-Guard, Tri-bar/Four-bar, PowerGlide, and TightWire.

For more than 60 years, U-S Safety Trolley has been a leader in customisable, flexible power distribution for industrial sites. Recognising that electrical joints were the most common sources of problems in crane electrification, U-S Safety Trolley engineers designed four unique “no-joint” products to meet the needs of industry: Span-Guard, Tri-bar/Four-bar, PowerGlide, and TightWire.

Span-Guard

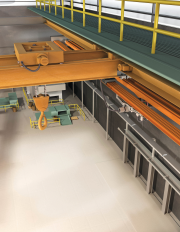

Plant managers, engineers, crane operators, and others with extensive crane experience know that electrical joints are the most common source of crane electrification problems. Among other things, electrical joints become loose over time, overheat, expand and contract, and can cause a loss of power. Span-Guard was the first continuous, joint-free electric conductor bar introduced. Span-Guard is uniquely designed without joints in the copper conductor. And the flexible fully-enclosing insulated cover provides the most reliable, highest quality conductor system on the market. This jointless conductor is ideal for cranes, hoists, and moving equipment where problems and downtime cannot be tolerated.

Tri-bar/Four-bar

Tri-bar/Four-bar

Tri-Bar/Four-Bar continuous electrical conductor bar systems have been a longtime favourite among our customers. The joint-free construction, easy installation and maintenance, and custom fabrications make the Tri-Bar/Four-Bar the sensible choice in electric trolley bar systems.

PowerGlide

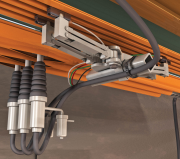

PowerGlide is a patented trolley system with retractable wheels that allows you to insert or remove the trolley anywhere along the conductor run. No more trap doors at the end of the electrical conductor run, or bending the bottom of the box track and forcing the trolley out. Just retract the trolley wheels for easy removal and inspection.

TightWire

TightWire is a continuous joint-free electrical conductor system that comes supplied in a portable roll. TightWire uses a single piece insulator containing 3 or 4 solid copper conductors. TightWire is compact and light weight which makes it fast and easy to install. Spring tension is applied from the end assemblies which keep the system strong and straight and only requires 10 feet spacing between hangers. Fewer supports translate into quicker installation time.

TightWire is a continuous joint-free electrical conductor system that comes supplied in a portable roll. TightWire uses a single piece insulator containing 3 or 4 solid copper conductors. TightWire is compact and light weight which makes it fast and easy to install. Spring tension is applied from the end assemblies which keep the system strong and straight and only requires 10 feet spacing between hangers. Fewer supports translate into quicker installation time.

To learn more about our reliable and safe power options for industry, visit USSafetyTrolley.com.